2012 in Review

Highlights from our Sustainable Customers Pillar of Performance in 2012 include:

- completed the pilot process noted in 2011 on four new product design projects and two existing products to understand the effectiveness of our DfE indicators and tools.

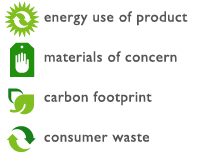

- updated the set of DfE indicators based on the pilot process to now include Consumer Waste and Carbon Footprint indicators, replacing Materials Consumption, Materials Source and End-of-Life Waste indicators.

- completed the Brainstorm Tool for use by the NPD project team in discussing opportunities for achieveing a 'trifecta' - better for customers (in terms of performance), better for Brady (in terms of cost profile), and better for the environment.

- established the DfE mentor program to help product development teams use the tools developed to support their thinking about sustainability throughout the NPD process

- began updating our new product development documents to incorporate DfE indicators into the development and stage-gate processes. This update will be completed in 2013.

- worked with our marketing teams to apply sustainability-focused knowledge in identifying new product opportunities

In 2012 the Sustainable Customer Council finanized an action plan that includes:

- Evaluating the sustainability profile of every product development and redesign project and then utilizing the data to enhance product sustainability

- Engaging focused markets to provide solutions for future sustainability needs

Sustainable customers 2012 success stories

PDC Creates More Sustainable Product for Key Market Segment Report-Out Contest Winner Submitted By Jodi Claus Brady’s recently acquired company Precision Dynamics (PDC) provides patient identification products for the healthcare industry. A common practice in Veteran's Administration hospitals is to print a 1”x10”wristband on a 3”x11”sheet, creating 2”of waste materials for every wristband printed. PDC’s teams worked to develop a wristband which can be printed on a roll of 100 labels with absolutely no material waste, using a printer which requires less space and less energy to run than traditional printers. |

|

| Digital Development Teams Adopt SCRUM Development Methodology Report-Out Contest Winner Submitted By Kelley Yunk Brady's Digital Development teams created a more predictable delivery model with higher productivity, reduced overtime and improved morale that resulted in on-time delivery of over 95% along with estimated savings of up to $100,000 per year by adopting SCRUM development methodology which is based on Lean Continuous Improvement principles. |

|

| Daikin Industries Chooses Brady as Green Supplier Brady's sustainability efforts not only improve company performance, but also encourage relationships with new customers. In 2012, Daikin Industries, the world's leading HVAC (Heating, Ventilation, Air Conditioning) company chose Brady as a preferred supplier, due in large part to Brady's sustainability program. Daikin's supplier requirements include a commitment to managing the environmental impact of operations. Daikin recognized Brady's continuous efforts to supply climate-neutral materials, reduce packaging materials, lower CO2 levels, reduce waste, and consider the environmental impact of transport and shipping. Daikin was also particularly interested in Brady's environmental management system certification and its Design for Environment (DfE) program as indicators that Brady shares Daikin's concern for the environment. |

|